Dassault Systèmes ziet sleutelrol voor Simulia in 3D printen

Simulatie gaat een grote rol spelen in 3D printen. Niet alleen simulatie van het ontwerp, ook van de materialen en het AM proces zelf. Dat zegt Subham Sett, directeur Simulia Strategic Initiatives bij Dassault Systèmes. In de toekomst denkt hij zelfs materialen te kunnen ontwerpen tegelijk met het productdesign.

3D printen centraal op Science in the Age of Experience 2017 event

Deze week houdt Dassault Systèmes voor de tweede keer in de VS een conferentie waar zo’n 700 wetenschappers aan deelnemen. Voor het eerst vindt als onderdeel van dit driedaagse Science in the Age of Experience evenement op de eerste dag het Additive Manufacturing Symposium plaats, dat grotendeels in het teken staat van 3D printen.

Doorbraak als productietechnologie

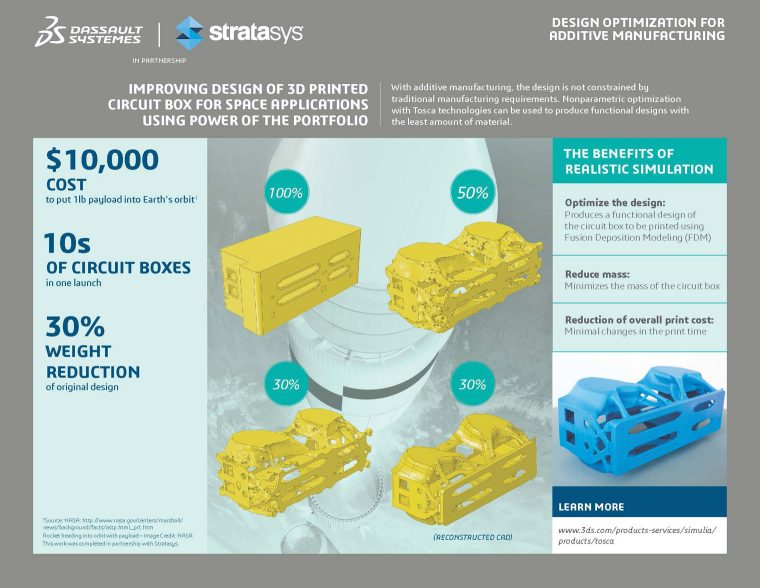

Op de afgelopen editie van SolidWorks World bleek al hoe sterk Dassault Systèmes inzet op additive manufacturing. Onder andere werd er een partnership met Stratasys aangekondigd. Verleden jaar op Formnext demonstreerde Renishaw de integratie van Catia-applicaties in de software voor de 3D metaalprinter. Hoe belangrijk de ontwikkelaar van design- en simulatiesoftware 3D printen vindt, blijkt eveneens uit een interview met Subham Sett op het Noord-Amerikaanse Simulia-blog. “We zijn getuige van de volgende mijlpaal, de brede acceptatie van additive manufacturing technologie. Oorspronkelijk uitgevonden voor prototyping, zien we nu de doorbraak van veel meer functionele engineering toepassingen. Met nieuwe processen die er aan komen die delen produceren in een tempo dat in de nabije toekomst volume productie of mass customization mogelijk maakt”, zegt hij hierin.

Simulia speelt rol in elke stap AM proces

Subham Sett ziet simulatie een sleutelrol spelen in de hele additive manufacturing workflow. Vanaf het productontwerp tot en met postprocessing. De simulatieapplicaties van Simulia kunnen in elke fase een rol spelen. Daarom werkt Dassault Systèmes aan de integratie van de simulatietechnologie in de belangrijkste designapplicaties van het bedrijf. Volgens hem leent het 3DEXPERIENCE-platform zich bij uitstek daarvoor. Interessant is de opmerking die Subham in het blog-artikel maakt over het Biovia-merk, simulatieapplicaties voor materialen. Hij ziet ook dit in de toekomst integreren in de designapplicaties en de aansturing van de 3D printers. “Over additive manufacturing wordt meestal gesproken in de context van vormvrijheid. Maar door atomen toe te voegen aan het vliegtuig, kunnen we een materiaal voor een bepaald doel creëren in plaats van een doel voor een materiaal.”

Resultaten onderzoekprojecten

Het Additive Manufacturing Symposium is vooral bedoeld om vanuit de wetenschappelijke hoek en de sleutelfiguren in de AM industrie te horen over hun ervaringen met zaken als design voor AM, materialen, certificering, et cetera. Adidas presenteert bijvoorbeeld de ervaringen met de 3D geprinte sportschoen; het onderzoekscentrum van United Technologies laat zien hoe ze het laserpoederbed voor 3D printen kunnen modelleren op basis van fysische eigenschappen. Dassault Systèmes zelf presenteert tijdens de conferentie resultaten van veel onderzoeksprojecten die het afgelopen jaar hebben gespeeld.

In de komende editie van 3D Print magazine verschijnt een uitgebreid artikel over de rol die Dassault Systèmes ziet voor simulatie in de doorbraak van 3D printen als productietechniek. Hierin komt de opinie van Subham Sett uitgebreid aan bod.