SLM Solutions breidt uit in Frankrijk en Italië

SLM Solutions heeft zowel in Frankrijk als Italië eigen dochterondernemingen opgericht. De fabrikant van 3D metaalprinters wil daarmee dichterbij de klanten zijn in deze belangrijke AM markten. De vestigingen moeten vooral een signaal afgeven dat SLM Solutions langdurige relaties met klanten wil aangaan.

3D metaalprinterfabrikant mikt op langjarige raamcontracten met grote klanten

Ook SLM Solutions breidt het internationale netwerk van dochterbedrijven dus uit. Uwe Bögershausen, CFO, ziet hierin een middel om het vertrouwen van grote partijen te winnen. Datzelfde is al eerder gedaan in Singapore, China en India. “Alleen al dit jaar verwachten we 40 miljoen euro omzet uit de raamcontracten die we in Azië met grote partijen hebben gesloten. Met de vestigingen in Italië en Frankrijk willen we ook in Europa verdere raamcontracten gaan afsluiten.” Het Duitse bedrijf wil het netwerk van vestigingen nog verder uitbreiden in Azië en Noord Amerika.

Gesloten workflow

Een van de meest recente ontwikkelingen die SLM Solutions naar de markt brengt is de SLM 500 machine met een bouwvolume van 500 bij 280 bij 365 mm en multilasertechnologie (maximaal 4 lasers van 700W gelijktijdig). Daarnaast biedt het met deze machine een zogenaamd Closed Loop AM systeem aan, wat bij SLM Solutions betekent dat vanaf het voorbereiden van de digitale 3D files tot en met het recyclen van het overtollig poeder in één gesloten proces gebeurt.

Presentatie op TechniShow

Deze week staat SLM Solutions met een 3D metaalprinter op het themaplein 3D op de Technishow. Hier presenteert het bedrijf zich samen met de Benelux dealer EKZO.

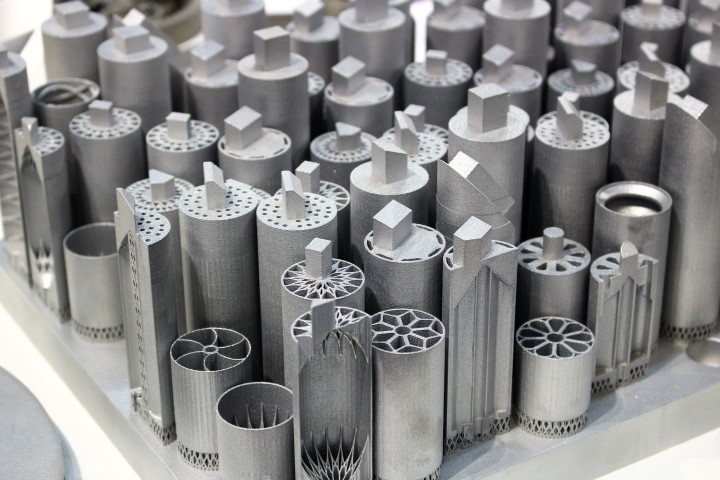

FOTO: een van de Duitse klanten van SLM Solutions is Volkswagen. Op de foto een printjob van VW.