- Medium and large-sized machine shops, as well as foundries, are well positioned for metal additive manufacturing

- Data is the key to achieving a predictable AM process and to demonstrate quality

- Medical and aviation industries in particular are looking for solutions to simplify quality control in AM

- Will first time right ever be possible with AM?

Many manufacturing companies find the risks of investing in metal 3D printing too high. The AM process is surrounded by quite some uncertainties. During AM for Production (October 2nd at Mikrocentrum), Julien Magnien, senior AM engineer at Sirris, will show how you can remove many uncertainties by using data of all steps of the AM process. Will metal 3D printing ever really be a matter of pressing the start button?

Actually, medium and large-sized machine shops, as well as foundries, are well positioned for metal additive manufacturing. This is the opinion of Julien Magnien, researcher at the Belgian research institute for the manufacturing industry Sirris. “They have experience with milling; they have the infrastructure for machining. They are aware of what tolerances mean, internal stresses in material, surface roughness, heat treatment. With a profile like that, it’s easier to get into the AM industry than companies starting from scratch.” And just as important: machining companies sometimes have to say no because parts are too complex to mill or turn. If they can make it with metal 3D printing, they have a business case.

You can find a Dutch summary of this article here

Why don’t they dare?

Sounds logical, but most metal companies ignore the consequences of additive manufacturing integration. The machining companies do not dare to invest in AM. And Julien Magnien understands that in a way. The investment risk with the new, unknown AM technology is greater than with several centuries old machining technology. The mindset is completely different. The high investments are the first barrier. The budget for a laser metal powder bed system often doubles by the time you have made all the necessary investments (oven, handling, storage, quality control, raw material, maintenance, software licences,…). If you don’t adjust the design, the cost of the parts is also much higher than when you mill or turn. If you are going to additively produce critical parts, you run into the problem of validation and qualification. There are standards and norms for CNC milled parts. For additive manufacturing, this information is hardly available.

Medium and large-sized machine shops, as well as foundries, are well positioned for metal additive manufacturing

Fragmented AM value chain

And then there is the fourth reason: the AM value chain is fragmented. Julien Magnien: “Your part may look good, but there are still many steps to be taken to make it a good part. And then your initial budget explodes if you haven’t taken this into account.” Julien Magnien is referring to operations such as removing support structures, milling interfaces, smoothing the surface, possible heat treatment and quality controls. It has been sufficiently demonstrated that AM works; airplanes and shuttles are flying with AM parts, patients regain mobility thanks to customs implants and internet is full of use-cases showing the great added value of AM parts. But currently it is a dream to think that you will immediately get the right quality the first time without solid background. These many uncertainties legitimately scare companies off.

The biggest challenge in metal additive manufacturing is predictable quality

AM for Production covers complete workflow

Julien Magnien is one of the speakers at AM for Production (2 October at Mikrocentrum in Veldhoven). The program covers all steps in the process because, according to chairman Samuel Tonneslan (at Brainport Development Project Lead for the 3DoP project), additive manufacturing involves more than buying a metal printer. “I also think that all the back-end things that come with it are challenging. It’s not a matter of buying a metal printer and turning it on. You have to train your engineers, you have to learn how to design for AM, you step into new supply chains. You have to implement a lot of things in your production.” Just as Julien Magnien says. Sometimes you also have to convince your customers about AM, to overcome social and cultural barriers.

Predictable quality

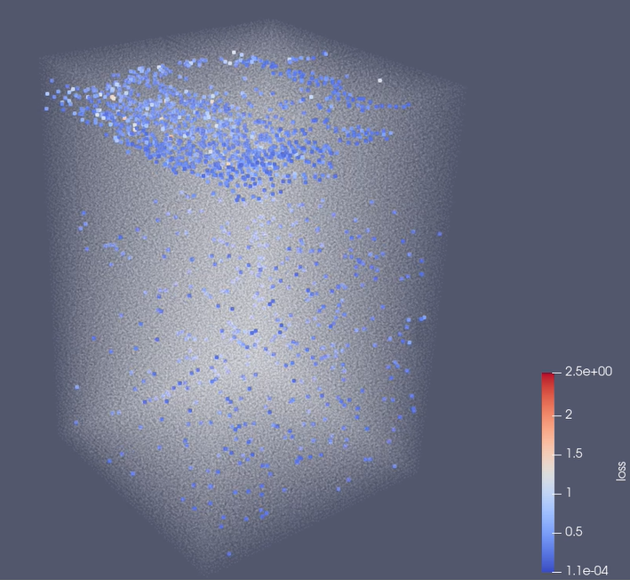

The biggest challenge in metal additive manufacturing is predictable quality of the end product. It depends on a large number of factors. Beside classical process parameters (laser power, speed, layer thickness & hatch space), you can have issues with how even is the powder layer, the oxygen content in the build chamber, the position of the workpiece in the chamber, and for some materials even how well the powder has been handled. Sirris has a special research laboratory that only deals with the powder. A test in which aluminium powder had only been in contact with the outside air for 20 minutes already led to a slightly different spread in the machine. This mainly plays a role with reactive materials, less with e.g. stainless steel. Sirris is trying to find the limits in the laboratory. If you know them, you can adjust your working method accordingly. AM therefore requires specific knowledge on top of everything.

Data is the key to successful AM implementation

The Sirris researcher believes that data is the key to achieving a predictable AM process and to demonstrating quality, so that not every workpiece has to be fully examined with a CT scanner. The many sensors in AM machines (optical, near-infrared, acoustic sensors, 3D scanners and others) provide a huge amount of data of what happens in the process. Because the Laser Powder Bed Fusion machines print with a layer thickness of 30 microns, the smallest irregularity can already have an effect on the quality. With all this data, Julien Magnien explains, you can convince customers that the process has been done correctly. “They want full traceability because the AM process is unknown. If you offer that, they dare to go further.” In his presentation at AM for Production, Julien Magnien will elaborate on this data, the experiences that Sirris has with it and how you can use this data to ultimately demonstrate the quality of the workpieces. “We don’t just look at what happens in the build chamber, but also outside it. For example, we take powder samples before and after the build job to check whether it still meets the specs. We also track the heat treatment and we even track the operators, because otherwise you only see the graph and you never know why there is a spike in the oxygen level. Maybe because the operator has changed overflow bottles ?”

With transparency and traceability, companies could already start printing many more parts

Digital quality control

Sirris once made a report for a foreign client of all the data it collected during the production of only five parts. This ultimately resulted in 80 pages full of sensor data and the correlation between this data and the end quality. Julien Magnien believes that the confidence that you can gain with this in the short term is more important than certifications. Because by no means all components are certified, “With transparency and traceability, companies could already start printing many more parts.” In time, it will be possible to use this data for a kind of digital quality control. Technically, a lot is already possible. The bottleneck is the analysis of all the data. A six-day build job yielded 1 TB of data at Sirris. Julien Magnien estimates that for an average build job, you have to count on a few hundred gigabytes of data. “If you produce a hundred to two hundred jobs per machine per year, you make the cloud explode,” says the Sirris researcher, outlining the challenge. How do you extract the information from that amount of data with which you can demonstrate the quality or improve the process?

QA cost reduction

The medical and aviation industries in particular are looking for solutions to simplify quality control in AM and make it cheaper. The cost of this can now be up to half of the total cost of the part. Julien Magnien: “No one has a model in which you can analyse all the cross-connections between the data. Not even Sirris. We’ve narrowed this down to six interfaces, but you want one.” Because six interfaces means that you still need specialists to find the correlation between the data. Recently, under the leadership of Materialise, the Valid3D project was started. This is a project within the Eureka Cluster (software innovation) in which Sirris is also participating alongside Dutch and Turkish companies and universities. The goal is to connect all available process data and use it to train AI models, so that the shape can already be validated with QA results in the design phase of a product. “We can already estimate where problems arise.

First time right

The ultimate goal is to end up at push the button, says Julien Magnien. AM is a process which does not require human intervention during manufacturing compared to conventional machining. So, if you have a good part design and good close-loop control during the process, you can produce high quality parts. And if a process data-based “AI tool” is able to provide this based on few inputs, then even an SME could start producing first time right, from scratch.

In their presentations, the speakers at AM for Production – in control of quality follow the entire AM workflow and how to guarantee quality in every process step. Speakers will come from the high-tech OEMs ASML and Thermo Fisher, knowledge institutions such as Sirris, Tilburg University and University of Twente, the manufacturers of AM systems such as Additive Industries and Renishaw and users such as KMWE. AM for Production will take place on October 2 at Mikrocentrum. More information about te program an how to participate can be found here.