As a 3D printing service company, 3Faktur in Jena (Germany) has moved far beyond the stage of prototypes. The majority of the 250,000 parts printed annually are for end applications. “Our customers don’t want inventories, which is why they choose 3D printing. That provides us with the challenge of making the batches the same quality every time,” says Markus May, CTO. Automation is therefore the key word in the German company’s R&D activities.

Markus May founded 3Faktur together with Johannes Zaremba in 2014. Today, the company – with its 12 employees – 3D prints around a quarter of a million parts each year. Most of these parts find their way into German and European mechanical engineering companies. “That’s where additive manufacturing makes economic sense,” says Markus May. In mechanical engineering, series are often small. A few hundred parts, sometimes a few thousand on an annual basis. If you then choose 3D printing, you no longer have to keep stocks. And as a machine builder you increase flexibility. Between orders, you can adjust the design if necessary.

Not keeping inventories

Markus May notes that flexibility and speed are the triggers for machine builders to look at additive manufacturing as a manufacturing technique. “Function integration and other benefits don’t come into the picture until later. They start with relatively simple parts and then manufacturing starts to grow. But still only a minority exploit capabilities like function integration. Flexible on-demand production remains the most important component for machine builders; they no longer need to keep stock.” In Jena, one sees growing interest from other sectors. Think of the automotive industry, manufacturers of medical devices and biotech. So far, these are plastic parts, which 3Faktur produces with HP’s MultiJet Fusion 3D printer, among others. In 2025, the first 3D metal printer will also be commissioned. Sebastian Matthes, manager of R&D, brought that experience with him upon his arrival early in 2024.

The fact that 3D printing companies have to develop automation solutions themselves, hinders the industrialization of AM

Automation is necessary

For continuity, repeat orders are ideal in a manufacturing company. With 3D printing, they do provide an additional challenge: repeatability. According to Markus May, additive manufacturing is still a process in which errors can occur at multiple points in time. “That’s why we put a strong focus on automation.” 3Faktur develops many solutions itself but also cooperates with partners. So far, 3D printer manufacturers have missed an opportunity here, the entrepreneur believes. With other production techniques, such as CNC milling or injection molding, manufacturers build a complete process for their customer. “In our industry, you buy a 3D printer and that’s it. But the printer is only a small step in the overall process. We have to develop the solutions for the other steps in the process ourselves. This slows down the industrialization of additive manufacturing.”

Who pays the bill for innovation?

This insight brings him to the second biggest challenge for companies like 3Faktur. “Machine costs are relatively high; automation makes it even more expensive. At the end of the year, we must still have sufficient funds available to invest in innovation.” Attracting financing opportunities remains tricky, because sometimes these are high-risk projects that do not always lead to success. “This search for funding keeps us focussed,” May says. And the solutions 3Faktur develops, gives the company an edge in the market, which would be different if everyone could buy off-the-shelf processes.

The 3D printer is only a small step in the overall process. The lack of automation slows down the industrialization of additive manufacturing.

Markus May

Personalized advice

3Faktur has now automated the 3D printing process to a great extent, even including post processing. For example, the smoothing of the printed parts is already automated. The entire workflow is also digitized. The 3D printing plant in Jena operates paperless. This allows the twelve-employee strong team to produce a quarter of a million parts per year. The error rate of 0.3% is very low for this sector. Markus May attributes to this that not only to automation of the AM process, but also to the fact that 3Faktur gives customers a lot of personal advice in the beginning. “It is important that they understand what is essential, not only technically but also in terms of setting up business processes,” May explains. Once customers understand this insight, the need for advice gradually decreases.

Right at the start of 3DOP

Markus May is one of the initiators of the 3DOP project, together with Stefan Rink, CEO of AM-Flow. Both had been talking to each other for some time about the need to take automation a step further. When the opportunity arose to turn it into a European research project, Markus May immediately agreed. The company is participating in work package 5: Automation for 3D Printing’s Future. “We could have run the project one-on-one with AM-Flow, but because other parties, such as ZiggZagg and Oceanz, are now included, we have to look beyond our own scope. Of course these are competitors, but we learn from each other by exchanging information in the 3DOP project.” Moreover, through the European project, 3Faktur has gained direct access to other project partners, such as Hexagon.

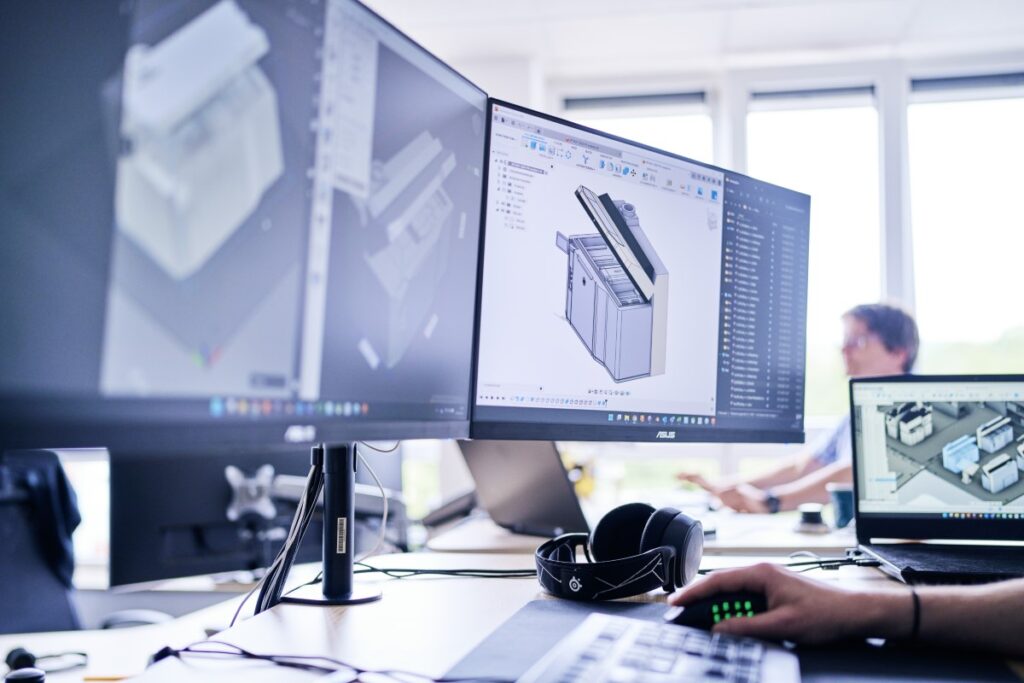

Above some photos of the sorting automation at 3Faktur, build by AM Flow in the 3DOP project.

Ambition: automatic control printability

3Faktur’s ambitions in the project reach far. Automatic quality control and sorting of the 3D printed pieces are two steps that the print service agency has already realized with AM-Flow’s systems. Markus May and Sebastian Matthes now want to use the data generated by AM-Flow’s QC module to automatically check the printability of designs at the front end of the process. “We then have fewer rejects and need to check fewer parts manually,” so Sebastian Matthes outlines the two benefits that 3Faktur can derive from this. Initially, this will mainly involve the geometric comparison of new workpieces with products that have already been printed before. At a later stage, it is conceivable that further follow-up steps can be taken with the help of Artificial Intelligence. With this, 3D printing service companies can make their production more efficient and thus expand the scope of application.

Evolution rather than revolution

Are we only at the beginning of the development of 3D printing? Markus May wouldn’t say so. He sees additive manufacturing as an evolution rather than a revolution. A lot has been achieved in recent years. Things that had to be done manually five years ago are now automated. “But 3D printing is not yet a process where the price of materials plays a major role, even though we are becoming more efficient each year.” By innovating, the industry is pushing the limit of the economic sense of 3D printing. “Injection molding will always have its place, but the boundary, the numbers up to when 3D printing is cheaper, will shift. This will allow our industry to expand the market.”