- Additive manufacturing was introduced at Valland back in 2016

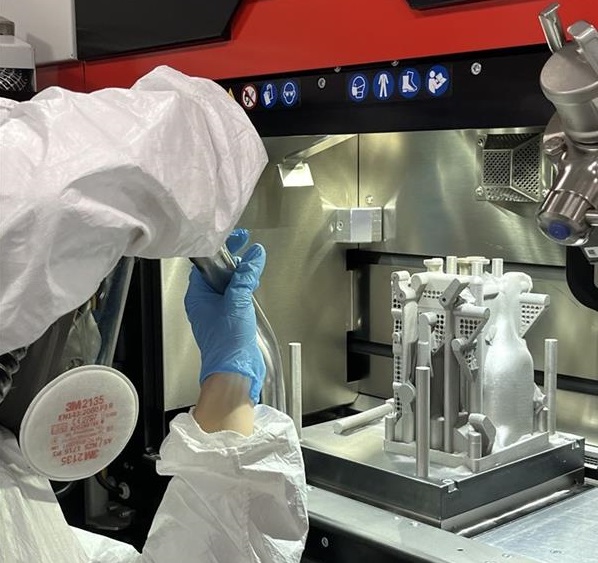

- The company now operates two metal AM-systems and five high performance polymer 3D printers

- Thanks to AM Valland is expanding in new industries

- Valland sees potential in repairing heavy duty components by AM

Valland (Italy) manufactures critical components for the Oil & Gas industry. Rush orders. Or one-offs that others don’t want to manufacture. Can Additive Manufacturing add value? At Valland they believe so, especially with a focus on sustainability. Participation in the 3DOP project should yield results that can convince customers in the Oil & Gas industry. But also, to tap new markets.

When Eng. Andrea Mondora started Valland in 2006, he was known in the Oil & Gas industry as a problem solver. Customers got him to start his own plant to produce industrial valves for the Oil & Gas industry that others were not producing. “These companies are still customers today,” says Alex Giorgini, R&D Manager at Valland, Italy.

Flexibility is one of the Italian company’s core values

Tackle problems others can’t of won’t

And producing valves that are not standard is still Valland’s core business. “We don’t produce to stock, but only when the customer needs the parts. Usually one-off products, custom made, with an elevated level of quality. We tackle problems that others can’t or won’t.” Fast track orders, for example. Or complex valves for Oil & Gas companies operating mainly in the North Sea, although in recent years Valland has also been supplying offshore companies in Asia and Latin America. Flexibility is one of the Italian company’s core values. With around 70 employees, Valland is on average smaller than other players in the market. “This allows us to be more flexible than others. We also have short lines to partner companies in the region, which allows us to choose the best supplier for each job,” adds Gianluca Acquistapace, AM manager.

We are the second Italian company to be certified for 3D printing with 316L, according to the DNV ST B203 standard

Exploring AM potential

Today, the family business in northern Italy is runned by the second generation: the founder’s daughter and son. Luisa Mondora has been the one who introduced Additive Manufacturing to the company. Back in 2016. She wanted to explore whether AM was a value-added technology for manufacturing critical Oil & Gas components. She was not deterred by the initial disappointing results. “The first results were poor. Technology was not sufficiently mature for our application at the time,” says Gianluca Acquistapace. Nevertheless, in 2020 Luisa Mondora decided to invest in a polymeric 3D printer to further investigate whether certain parts from the valves could be substituted by 3D printed ones. Gianluca Acquistapace joined the company a year later to lead the AM operations. And in 2022, Valland purchased its first metal 3D printer, a laser powder bed fusion system. Year 2024, Valland has two metal printers, both laser powder bed fusion systems – for stainless steel, aluminum, and nickel alloys – and five high-performance polymeric printers, as well for resins and filaments. This year, Valland has taken a major step toward adopting Additive Manufacturing as a manufacturing technology. Gianluca Acquistapace: “We are the second Italian company to be certified for 3D printing with 316L, according to the DNV ST B203 standard. We may therefore now sell certified AM parts.”

Read more about the cooperation of Valland and Guaranteed in 3DOP

Technology partner in new markets

The AM manager sees Additive Manufacturing as a means to further increase flexibility. AM can also facilitate the assembly process. Because Valland was one of the first suppliers to the Oil & Gas industry to invest in Additive Manufacturing, the company now has a competitive edge. The AM manager calls this a strategic advantage. Design freedom plays rather a modest role in this. For the company, the added value of Additive Manufacturing is in other benefits. That could be, for example, the assembly of the control panel of an actuator, which is less complex because of function integration with AM. AM also offers Valland the opportunity to tap new markets. “This allows us to seek customers in sectors other than the Oil & Gas industry, for example, energy, automotive and aerospace”, he said. “Our company is diversifying into other industries,” Alex Giorgini concurs. “We are building on the knowledge we have gained from critical components manufacturing, but applying it to other value chains that are new to us.” Valland has absolutely no ambition to grow into a 3D printing service center. “We want to add value to the products for our customers by carrying out the whole process. By being a technology partner for them.” Additive manufacturing, according to Alex Giorgini, can therefore very well exist next to the core competences of the company.

We also want to free up R&D resources to explore the innovative landscape

European cooperation

Previously, Valland has participated in European Vanguard projects. Now the company is one of the participants in the EU-funded 3DOP project. “European projects are very interesting for SMEs because they help discover opportunities and develop cooperation with other parties. This would not be possible without these projects,” Alex Giorgini says of why Valland participates in 3DOP. A second reason is that these types of practically focussed research projects help change the mindset in the company toward the application of innovative technology such as AM. “We don’t just want to be busy with our regular job, we also want to free up R&D resources to explore the innovative landscape. That’s part of our mission. Daring to get out of your comfort zone and look for new opportunities.” Valland participates within the 3DOP project in the 3D metal printing work package. For example, together with ProM facility of Trentino Sviluppo and Guaranteed, respectively Italian and Belgian participants in 3DOP, the possibility of using 3D metal printing to repair expensive components was investigated. It not only saves time but is also more sustainable because less material is wasted. “With the 3DOP project, we want to expand our knowledge and familiarize the industry with Additive Manufacturing. By showing real applications, confidence in AM as a technology grows,” says Alex Giorgini. The Oil & Gas industry is still working with outdated standards that have not always evolved to meet current technological demands. It is up to companies like Valland to demonstrate that AM products comply with them. In addition, Gianluca adds, they are gaining a lot of knowledge from the other partners in the 3DOP project. “Also from other AM techniques. Now it is too early to invest further, but we want to learn more about the other techniques.” Even the activities in the other project groups, which are often far removed from Valland’s core, the R&D manager finds interesting. Valland can learn a lot from the technical point of view of the medical companies, for example.

It is up to companies like Valland to demonstrate that AM products comply with standards in Oil & Gas

Sustainability

The companies researching and further developing 3D metal printing in the 3DOP project are on track. Few different products have been delivered, for example a valve seat repaired and repurposed with AM. Valland has also verified and validated this product. This means, among other things, that the components repaired by ProM facility of Trentino Sviluppo, another partner, are being pressure tested by Valland for, among other things, leak-tightness. The first signs point in the right direction. “The results are positive. I think there is potential in the application to repair valve components and similar components with Additive Manufacturing,” says R&D manager Alex Giorgini. A key issue in the final evaluation is cost: is it cheaper to repair than make a new part? Still, he believes you don’t just look at cost. “Another concern is sustainability. In the 3DOP project, we did not provide an LCA, but we certainly put this point on the table. We know from other use cases that repairing could be more sustainable.” Especially if in the future Valland can get the feedstock for the 3D metal printers from recycled discarded components. One of the parties in the 3DOP project is researching how to produce metal powder by recycling end-of-life components from the Oil & Gas industry. “This impact can be big,” says Alex Giorgini. “If we can get our feedstock from the old components, we make a lot of environmental impact and really move toward a circular economy. Gianluca adds: “Especially if you eventually couple that with decentralized manufacturing, which Additive Manufacturing lends itself well to. On-demand and on-site production where the components are needed is possible. Then transportation is eliminated, and in a country like Norway we produce with green energy even more sustainably.”