- The AM infrastructure of Porin is available to Croatian companies to explore the technology, conduct tests and possibly even start with production.

- Rijeka development agency Porin participates first of all in the work package about 3D printing of tools and moulds for injection moulding and embedded electronics

- European innovation projects like 3DOP provide much more insights and knowledge than just the work package in which you participate yourself

For Nenad Antolović, the most exciting phase of the European 3DOP project starts in the fall of 2024. By then, the technical solutions to be developed within the project must be ready. After that, the focus will shift to attracting investments so that Croatian companies, among others, can integrate 3D printing into their business. “Then we will definitely promote the use of additive manufacturing technology, for example in the dental industry that has a strong ecosystem here,” said Nenad Antolović, director of Rijeka Development Agency Porin.

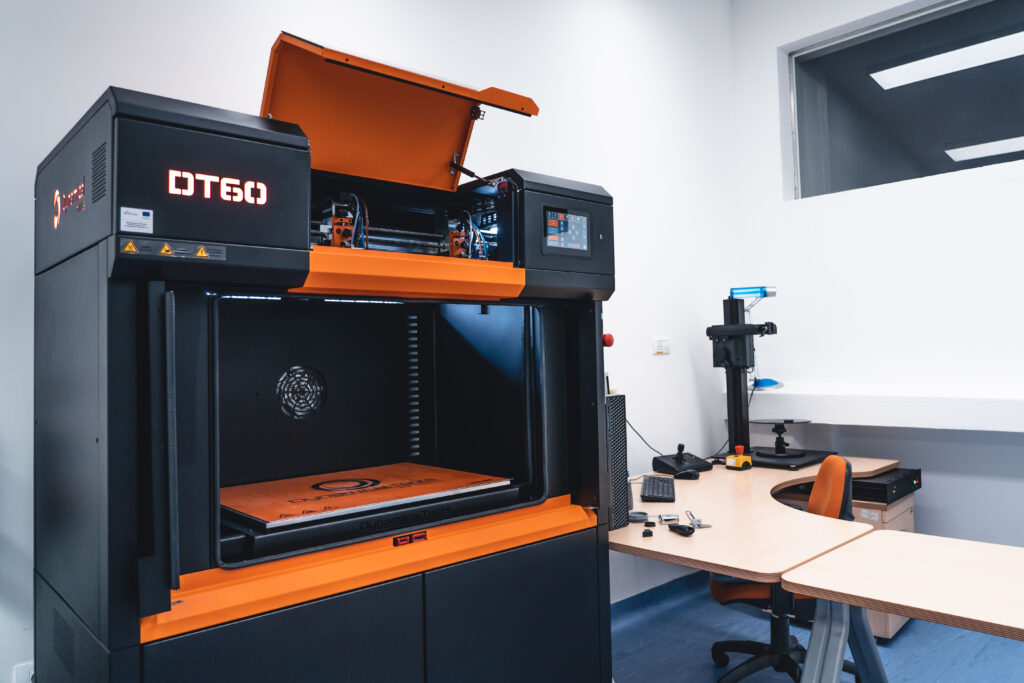

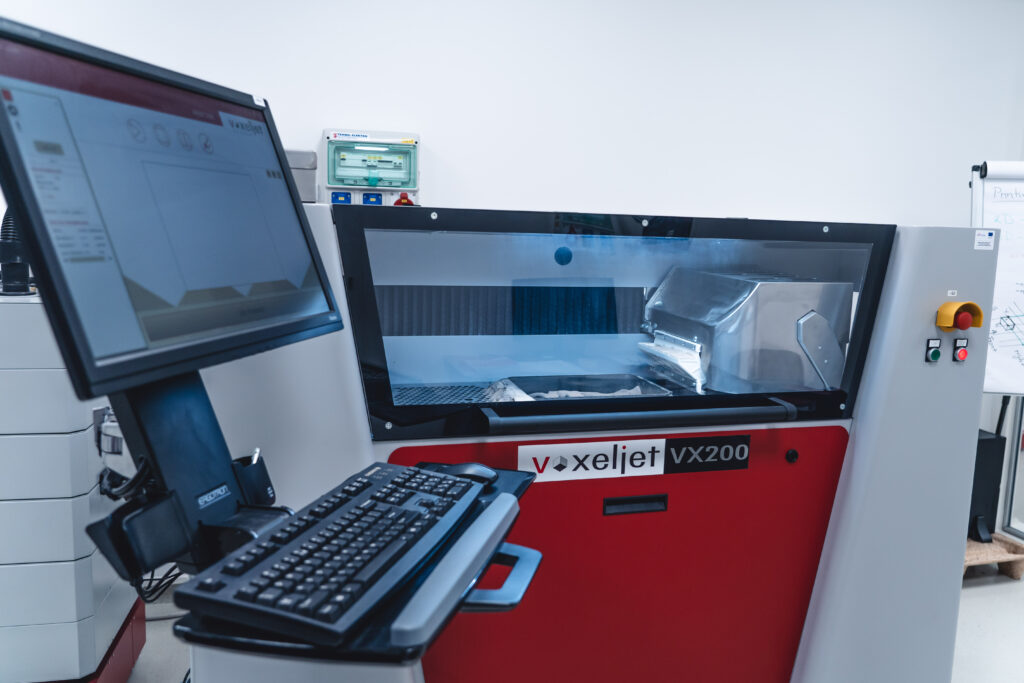

Porin is a development company in Rijeka, the third largest city in Croatia. Nowadays, the region around the city on the coast of the Adriatic Sea mainly lives from tourism. However, in the former Yugoslavia, Rijeka was a flourishing industrial and port city. After the privatization process in the 1990s, most of the industry disappeared. Porin now operates from the Torpedo Production Park, housed in the former Torpedo complex, a legacy of the city’s industrial heyday. Porins’ incubator that accommodates starters and innovative companies, is a training center for CNC and 3D printing technology (and CAD) and houses an innovation center. During the reconstruction of the building, Porin and the city of Rijeka invested in 3D printers, both for polymers and metals. In addition to the EOS M100 and M280 3D metal printers, Porin has a Dynamical DT 60 FDM printer for high-quality polymers and the Voxeljet VX 200 sand printer. “We are the first in Croatia with a sand printer for moulds and cores,” says Nenad Antolović.

Exploring technology

This AM infrastructure is available to Croatian companies to explore the technology, conduct tests and possibly even start with production. Two experts are employed in Porin to support companies in this. “Entrepreneurs can 3D print the parts here and then commercialize them themselves.” It is not only industrial and medical companies that use Porin’s 3D printing facilities. There is also a lot of printing for the artistic sector in the region. “We scanned important pieces of art for the Museum of modern and contemporary art Rijeka and then printed them.” In the field of 3D printing, Porin works closely with the Faculty of engineering of the University of Rijeka. But industry has also found its way to the innovation center. For example, parts for the automotive and maritime industries were printed.

Growing interest

Interest in 3D printing in Croatia is growing, notes Nenad Antolović. Porin has established a 3D printing hub together with two other organizations, so that they have coverage throughout the country. A sector that is of great interest is the dental industry. This sector is strongly focussed on innovation. “Because we are close to Italy and Austria, many people come here for dental care. We offer dental care cheaper through many outpatient clinics and private clinics,” says Nenad Antolović. There is great interest in the dental industry in 3D printing, as was recently demonstrated during a congress on the possibilities of 3D printing in the medical and dental industry. “This congress was a first step. We are also working with the Faculty of engineering to put the knowledge into practice.”

It is crucial that we highlight the importance of additive manufacturing and attract investment

3D printed moulds

Rijeka development agency Porin participates first of all in the work package about 3D printing of tools and moulds for injection moulding and embedded electronics. With the technology developed in this sub-project, the companies in the incubator in Rijeka can make advanced sensors. Porin wants to deliver an automated 3D printing pilot line in which 3D printing is integrated. “3DOP is interesting for us because it delivers more than the solution we are working on together,” is how the Porin director describes their participation in this European project. These types of European innovation projects provide much more insights and knowledge than just the work package in which you participate yourself. “You also get the bigger picture when the project is completed. Tech giants from different countries and sectors, both public and private organizations, participate in 3DOP. The online and in-person meetings are good for learning from each other.” In the 3DOP project, a group of European companies and research institutions are also working on innovations in the field of dental printing, an area that is closely monitored in Croatia.

Attract investors

Nenad Antolović is also looking forward to the results of work package 6, in which Porin is also participating. In this work package, in the final year of 3DOP, plans are being developed to interest investors in the innovations developed in the other work packages so that they can be brought to the market faster. At the same time, the participants in this work package want to remove barriers for companies to start 3D printing. The 3DOP project is the first European-funded project in which the commercialization of innovations plays an explicit role. “This distinguishes 3DOP from other EU projects. We need to justify the developments by finding investors.” Nenad Antolović thinks this is perhaps the most important part of the 3DOP project. “It is crucial that we highlight the importance of additive manufacturing and attract investment,” he says. Porin, as a local development agency, does not have the financial funds to drive this on a large scale, but will do everything possible to promote the technology to the business community as well as to bring 3D printing to a wider audience. The ambitions are big. “We are going to promote the first call at the end of 2024 not only among industry, but also in the dental ecosystem here.”

As soon as the products of the 3DOP project are ready, the results will become more visible and we can start yelling.” The network Porin builds up through participation in 3DOP will certainly be helpful in this regard.