At the start of the 3DoP project, the Belgian startup ValCUN only had a proof of concept of the proprietary Molten Metal Deposition technology for printing aluminium. Three years later, the first machine has been delivered, the scalability of the technology has been demonstrated in a concrete business case, and ValCUN has shown the second generation printhead at Formnext, which can be integrated into CNC machines and robots. “We were able to get quite a lot out of the 3DoP project,” says Jonas Galle, co-founder and CEO.

After steel, aluminum is the most widely used material worldwide in the metal industry. Nevertheless, metal additive manufacturing focuses usually on materials such as titanium and Inconel. This prompted Jonas Galle and – later – Jan De Pauw, co-founder and CTO, to develop an affordable printing technology for the manufacturing industry, especially for aluminum. The barriers of other AM technologies to effectively work with aluminum are high, partly due to the high investment costs and partly due to the low cost-effectiveness, which means that the added value of AM is in many cases economically not interesting.

Because standard aluminum wire is used, and the workpieces are easily removed from the build plate by hand, the cost per part is significantly lower

Making 3D printing economically and industrially scalable

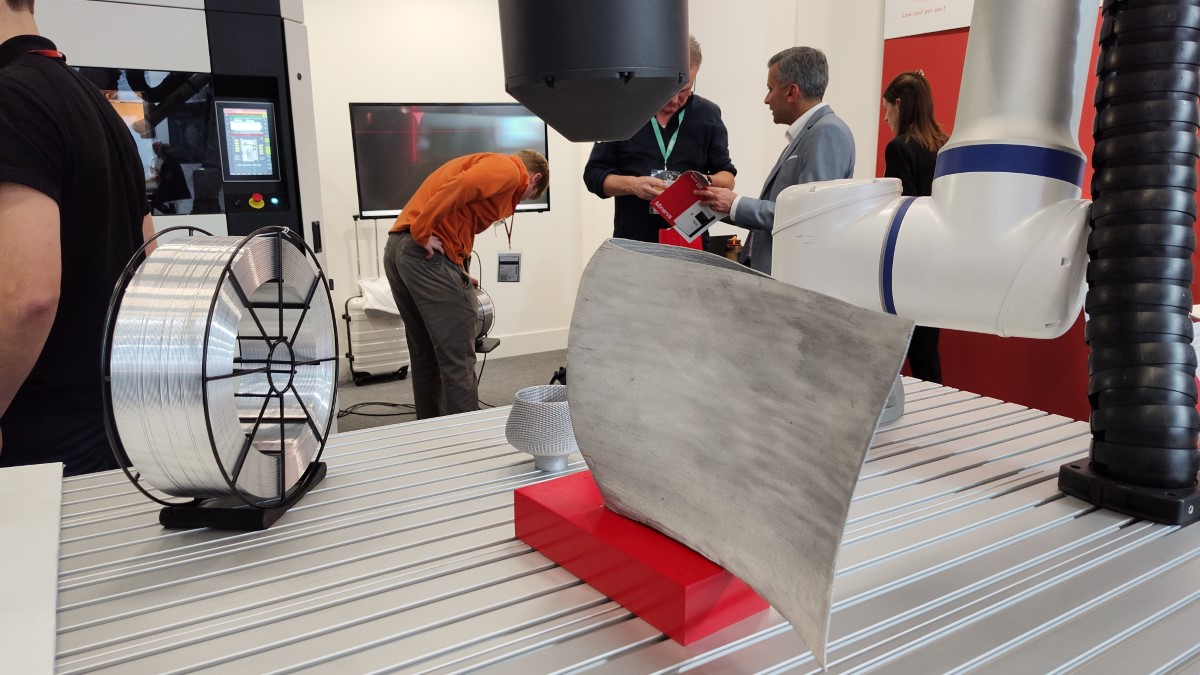

With the Molten Metal Deposition technology, ValCUN wants to make 3D printing with aluminum economical and scalable within the manufacturing industry, exactly what the 3DoP project also pursues as its main goal. The aluminum wire – or even scrap – is melted locally in the printhead, requiring 3 to 8 times less energy than in an LPBF process, for example. In addition to energy savings, the main advantage of this the aluminium wire is that the risk of deformation (due to the heat input) or cracking is minimal. Because standard aluminum wire is used, and the workpieces are easily removed from the build plate by hand, the cost per part is significantly lower. Up to 90%. With the new Remus printhead, ValCUN goes one step further. It can be placed on a robot arm or integrated into a CNC machine and allows independence from the build volume. This further reduces the investment costs and increases the application possibilities. With the new printhead, it is also possible to print on existing components.

How has ValCUN evolved over the three years of the 3DoP project?

Jonas Galle: “At the start in 2022, we had no machine, no design, only the ambition to bring 3D printing technology for aluminum to the industry. In the first year of the project, we were at Formnext with our first machine, which we sold to Sirris in early 2024 and installed later that year. We worked out the first potential business case with Addcat (another partner in the project) and functionally tested a first prototype. At Formnext 2025, we presented the new printhead, which we will commercially market in 2026. So participating in the project has certainly added value to us.”

ValCUN has developed a business case together with 3DoP project partner Addcat. Can you tell us more about that?

Jonas Galle: “We already had contacts because we wanted to do a feasibility study together. However, the resources for this were lacking. Through Addcat, we eventually ended up in 3DoP and were able to develop the first potential business case and functionally test the first prototype. Not a prototype print or a tool, but a product for which production must be scalable, and cost and performance were important. With Addcat’s catalyst, we have shown the added value of our technology. Together we have made a whitepaper and infographic about it in which we share the results and performance. When I pitched this case on Formnext to potential investors, it came across well. Technology is important, but the effective application that allows you to create business is even more important.”

From startup to scale-up

ValCUN is currently in the transition from startup to scale-up. Jonas Galle does not hide the fact that the financial support from the project has been important. “The machine would come to life anyhow, just not in this short notice. Apart from the financial aspect, contacts play a very important role. We let the developments be partly guided by the feedback we receive from other project partners.”

Everything that is needed to 3D print aluminum is now in the printhead

Driven by market demand

The development of the new Remus 1.0 printhead mainly stems from a case in the automotive industry, HVAC, repair and space applications, where both large scale and adding structures to existing parts have great added value. ValCUN adds an additional process step in the Remus printhead, namely the use of plasma to preheat the workpiece and to prevent oxidation after 3D printing, a solution that is already included in the original patent. “Another business case involved 3D printing on existing parts, which we can do with the Remus head too,” adds Jonas Galle. “Everything that is needed to 3D print aluminum is now in the printhead.” This has limitations in terms of dimensions, which is necessary to 3D print larger parts. The Remus printhead is also integrated into the Minerva 3D printer. And depending on the requirements of the market, a machine with a larger platform is developed. “We are really guided by market demand and business cases.”

You got a lot out of the project. Are there also cases that have been less successful?

Jonas Galle: “We actually made too little use of the collaboration with partners, apart from the one with Addcat and the one with Sirris. During meetings there was a spark to do something together, but in concrete terms we have only built-up good contacts with Trentino Sviluppo and f3nice. With f3nice, we see synergies to do something together for 3D printing for space, by recycling space applications and 3D printing the material again with our technology. With Trentino Sviluppo, we looked at how we can work together on Formnext, just like we work with Sirris.”

Shift towards business development

Now that the business cases are established, the hardware is mature for industrial applications, and the scalability has been demonstrated, ValCUN is looking for an investor for a capital round. In addition to working capital, they also hope to bring in expertise in the field of running a business. Jonas Galle: “We still have plenty of ideas to develop technologically, expansion on the materials side and the development of a closed loop process, so that both the G-code and the print parameters are generated on the basis of the 3D model and integrated into the toolpath. But upcoming year we will also move in the direction of business development and further development in function of that. ValCUN now has to become more than just playing with technology.”