The 3DoP project is gradually coming to an end. All the technical work is on track to achieve the two main objectives of the European AM project, says project lead Samuel Tonneslan. Can additive manufacturing now be more widely implemented in the manufacturing industry?

For Brainport Development, it was a no-brainer to lead the 3DoP project. The Brainport region -around Eindhoven- in the Netherlands is home to high-tech OEMs – such as ASML, Thermo Fisher Scientific and Additive Industries – and their ecosystem of larger and smaller suppliers. “It’s a very high-tech, high-complex type of product that is made in this region. And that is something additive manufacturing fits in well with,” says Samuel Tonneslan, on behalf of Brainport Development. This is the economic development company for Brainport, the region around Eindhoven. This is where the regional economic strategy is developed and executed, business is supported, and the high-tech sector is promoted worldwide.

If we can apply AM to less bulky, low-complexity components, it will meet the needs of the companies here

International contacts

So far, only a handful of companies use AM to produce highly complex parts. However, AM can be applied more widely, also in the production of less complex parts. Samuel Tonneslan: “If we can apply AM to less bulky, low-complexity components, more at the other end of the spectrum, it will meet the needs of the companies here. So, we wanted to invest in this direction with numerous innovative projects. And 3DOP was a great way to invest in companies here while expanding our networks and supply chains across Europe.” Because the region realizes that you cannot do everything yourself, Brainport Development therefore consciously seeks international cooperation. “The broad European network within 3DoP gives us access to other regions to learn from and work with.”

Niche applications

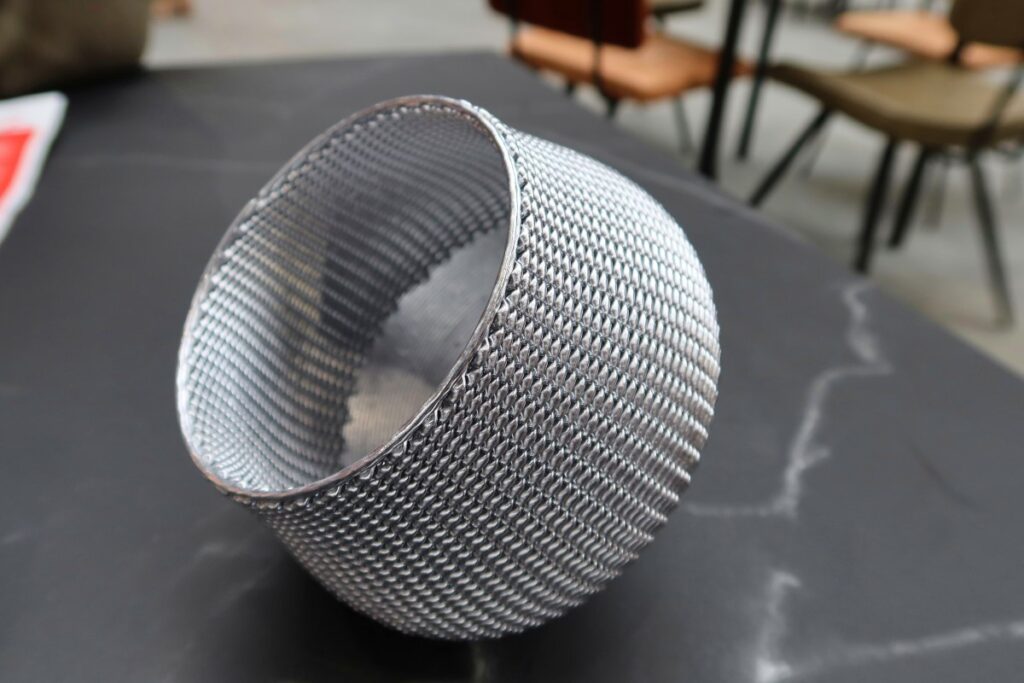

As with any manufacturing technology, companies that benefit the most pick up AM first. “The technique finds its niche in the production of high-tech and high-complexity components, such as in the application of Addcat where 3D metal printing makes their production of catalysis components cheaper and their technology more effective,” says Samuel Tonneslan. Addcat develops a plug-and-play system that completely degrades harmful and smelly volatile organic compounds. For many applications, the high costs are an obstacle to many applications. That is why the 3DoP project focuses on making AM technology more accessible.

More than a 3D printer

The project lead, with AM experience in the American space industry, does not think that this is the only obstacle. “Everything around AM is just as much a challenge. You do not just buy a printer and then turn it on. You must train your engineers. You must learn how to design for AM; while often making changes to your factory. It is good that companies are skeptical about these matters. It is up to the AM companies and organizations, such as Brainport Development, to coach people in this adoption process, to minimize and manage risks, to keep costs as low as possible and keep surprises to a minimum.” On these conditions, AM can land more broadly, even in applications where the technology adds value but is complementary to the other production techniques.

Project goals achieved

At the start of 3DoP, at Formnext 2022, the two important goals were to make additive manufacturing as a technology more production-ready and to reflect that in investments. “I think we are on track to see both goals achieved by the end of the project,” notes the project lead as the European project enters its final months. “New technologies have been developed and investments are being made in new business and sales.”

ValCUN as examle

As an example, he mentions ValCUN from Ghent, Belgium. Partly by participating in the 3DoP project, the startup has been able to accelerate the development of their low-cost aluminum 3D printer. The Minerva metal printer is an alternative for companies for whom a laser powder bed system is overkill, too expensive and too complex. “Thanks to the project, they have gained a lot of exposure and have really seen growth.” The second alternative metal printing technology was developed by Opiliones, which focused on alternative feedstock. Samuel Tonneslan: “Participation in the project has linked Opiliones to new partnerships and new customers for their technology.”

AM-Flow accelerates development

AM-Flow, which also operates from the Brainport region, is the third example of new technology whose development has accelerated thanks to 3DoP. AM Quality, the automated QA system for automatic inspection, solves a bottleneck in, for example, the dental industry when switching to metal printing.

Improving traditional industries

3DoP has also delivered concrete results internationally. Samuel Tonneslan points to the hybrid technology that TECOS has developed in Slovenia together with project partners. TECOS combines injection molding with additive manufacturing for advanced injection molding. “This is a good example of how a partner from a traditional industry improves the process with AM. The pilot line in Slovenia is up and running.” There are many more examples of how the 3DoP project has brought together European companies from different sectors to take additive manufacturing to the next level.

3DoP will also present results at Formnext

Even wider distribution

What makes 3DoP unique as a European innovation project is not only the participation of thirty-three partners but the sixth work package: SMEs, Innovation and Market Access. Developing technology is one thing, but ultimately it is about actually bringing this technology to the market. Investors are needed. Work Package (WP) 6 of the 3DoP project is about attracting investors. Through Tech Tour, several participants were prepared for pitching to investors and brought into contact with investors. “Attracting investors is really a challenge these days. However, Tech Tour has done a good job; they have earmarked companies that needed an investment and helped them connect with investors.” A special part of WP6 is the Open Call for 3DoP services. SMEs from all EU countries can have their ideas for the application of AM tested for feasibility by the project partners free of charge. For example, the knowledge about AM should be spread even more widely among the manufacturing industry. After an initial action, about ten companies are now working on testing 3DoP services. A second group will soon start. They are provided with technical services in the form of tests or demos of new products. And they receive support on the business side: they are linked to potential investment opportunities and cooperation partners. “To be honest, we had expected more spontaneous registrations for the Open Call. That is why we have adjusted the strategy and started approaching companies within our networks. That worked well because the interest is now greater. It gives more companies the opportunity to explore the possibilities of AM for their business.”

Follow-up

And that is good for the acceptance of additive manufacturing as a manufacturing technology, one of the goals of 3DoP. In the coming months, the various project partners will organize events to disseminate the knowledge gained in the project. 3DoP will also present results at Formnext and an official closing event will be organized at the end of this year. Samuel Tonneslan is convinced that these events will lead to the establishment of new connections between project partners and companies and knowledge institutions. “New value chains will emerge, with new business cases. I believe that all materials and knowledge will be promoted by us and the European Commission to make it as widely known as possible.”

Samuel Tonneslan does not expect a second 3DoP project. But he does see that project partners are already preparing smaller projects, with around 5 to 10 project partners for every upcoming project. Both in the Brainport region and Europe-wide, attention will continue to be paid to the further development of AM and its further distribution in the industry. “The EU wants to see the technology used even more widely. In the region, we see that it will mainly be about implementation. Here too, we continue to work to ensure that companies remain top of mind.”